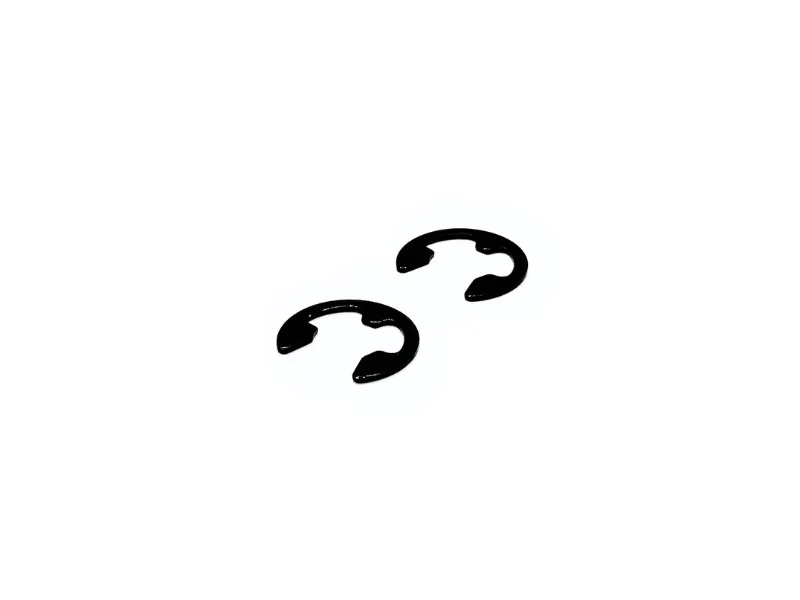

Washers and Retaining Rings (Circlips)

We supply the following types of washers as a custom washers manufacturer: washers, conical washers, accessory washers, flat washers, sealing washers, square washers, washer rings/support plates, and countersunk/serrated washers.

Available in a wide range of materials and specifications to meet industrial and construction requirements. Materials include carbon steel, stainless steel (e.g., 304, 316), aluminum alloy, copper, brass, and nylon engineering plastics. These materials provide excellent corrosion resistance, wear resistance, and high-temperature performance, ensuring long-term reliability and stability under harsh conditions.

Applications:

-

Flat Washers: The most common washer type, used in machinery, construction, and equipment to distribute load and prevent loosening of bolts and nuts.

-

Conical Washers: Provide precise support and adjustment, suitable for installations requiring angled positioning in special conditions.

-

Accessory Washers: Widely applied in machinery and accessory systems to ensure precision and stability during installation.

-

Sealing Washers: Offer excellent sealing performance, used in piping connections and for sealing liquids and gases to prevent leakage.

-

Square Washers: Provide a larger bearing surface, commonly used in special-shaped equipment for secure fastening.

-

Washer Rings / Support Plates: Applied where additional support and load distribution are required.

-

Countersunk / Serrated Washers: Maintain stability in vibrating environments and prevent fasteners from loosening.

In addition, we provide a variety of washers that comply with international standards, covering both metric and imperial specifications to meet the requirements of different regions and industries. Customized solutions are also available to design and manufacture washers tailored to your specific needs, ensuring optimal performance and application results.